EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

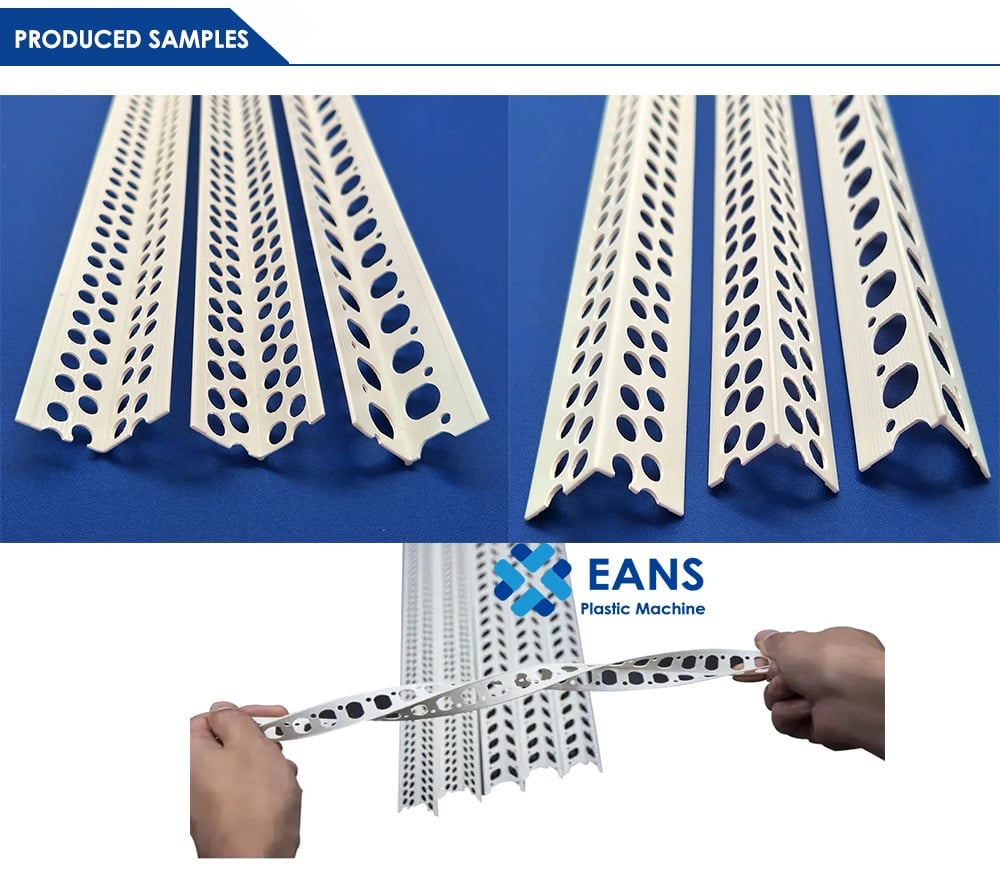

PVC corner beads production line is used to manufacture PVC corner beads with different section shape and height.

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Eletric: |

|

Temperature controller: |

|

Steel: |

|

Speed: |

|

Screw and barrel: |

|

Guarantee time: |

|

Votage: |

|

PVC corner bead production line is used to extrude PVC corner bead, angle trim, which is a kind of PVC profile particularly designed for protecting corners of wall and so on. It can makes corner beads 4 out or 6 out by changing the extrusion die mold.

PVC Wall Corner Beads Making Machine List:

1. Automatic raw materials feeder - 1 set

2. Twin screw extruder - 1 set

3. Mould - 1 set

4. Water cooling table - 1 set

5. Hauling off - 1 set

6. Automatic online punching cutting machine - 1 set

As a replacement for the traditional methods to repair wall corner, it has been extensively used for construction, decoration, and wall protection. Upon clients' request, we can equip punching, printing, coding or other additional equipment for the PVC profile extrusion line.

PVC Corner Beads Extrusion Machine Technical Parametes:

| Model | Mold | Extrusion Speed | Motor Power | Heating Power |

| SJ55/110 | 4/6 cavity | 150 KG/H | 22 KW | 12 KW |

| SJ65/132 | 6 cavity | 280 KG/H | 37 KW | 18 KW |

Features of PVC corner beads extrusion line:

- Fetching in Europe and America advanced technology and uniting with domestic condition, our company develop this production line.- This production line is used to manufacture PVC corner guards with different width and wall thickness

1. PVC Corner Beads Extruder

- Machine colors: white, blue, red or customized

- Automatic screw type feeding system, raw materials do not bridge, feeding stability

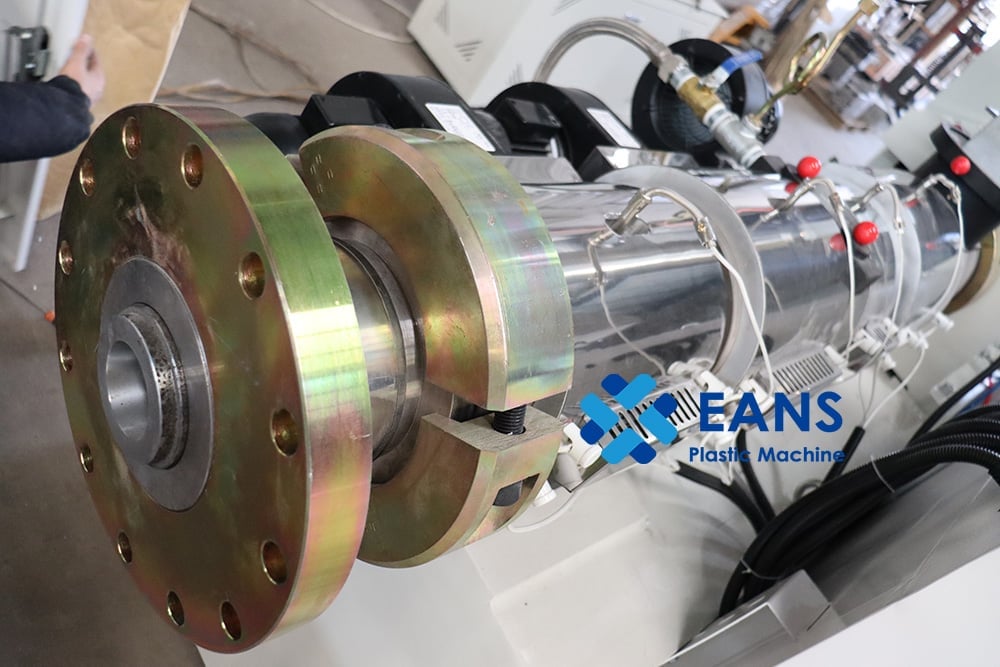

- Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

- Flange surface be nickel-coating treatment, ensure the stable extrusion

- Be equipped with ABB inverter, Siemens Motor and Schneider electrics, lower staring power, reduce voltage fluctuation.

2. PVC Corner Beads Mold

3. Online holes punching machine

FAQ:

Q1. Are you a factory or a trading company?

A1: EANS is a high-end export brand of EANS Group. We have our own factory, and many high-quality suppliers. We provide "all-in-one solusion" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed satisfaction, you will never overpay again.

Q2. Are there other machine not listed in the catalog?

A2. EANS provides all different types of plastic extrusion solutions. If you cannot find the exact machine you are looking for, please contact us, we will be happy to develop with you and become your long-term trustworthy Chinese factory!

Q3. Can I get free samples?

A3.EANS can send free samples. But you need to pay the cost of Express which can be reduced in the order of machine in the future.

Q4. How long will I receive the quotation?

A4. Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 8 hours.

Q5. How do I get response quickly?

A5. If you send email, whatsApp, WeChat to contact us, we promise to reply to you within 8 hours! WhatsApp is the best and 24 hours online:)