EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

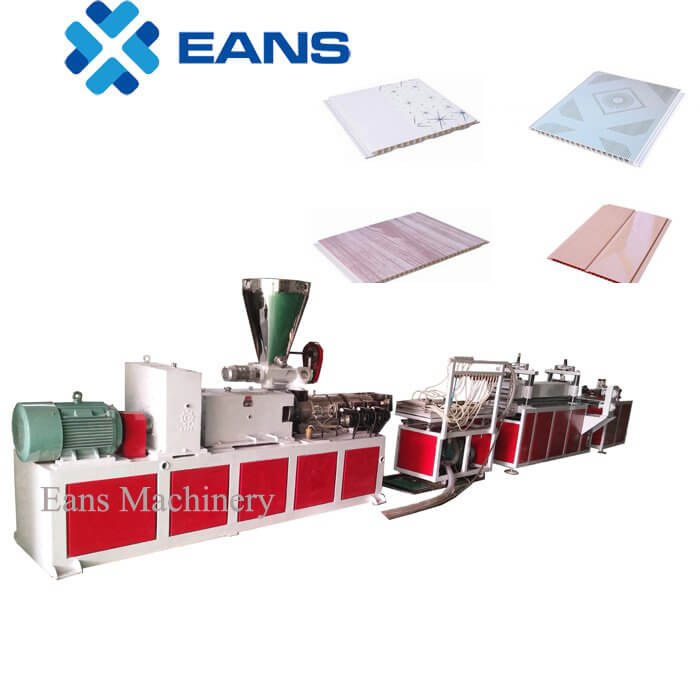

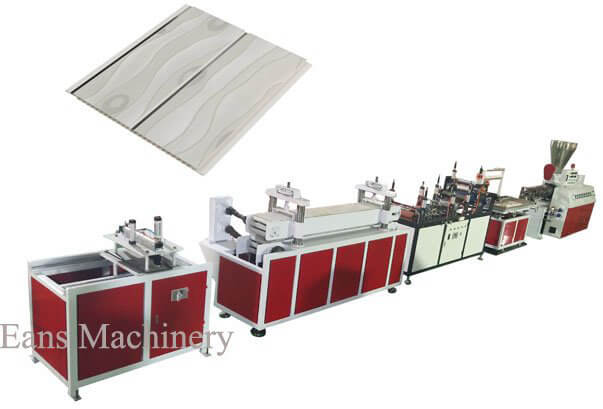

Plastic extrusion machine for PVC ceiling panel is used to produce PVC ceiling panel which can make different width,such as 200mm,250mm,300mm,400mm and 600*600mm.By changing mould,it can produce different shape and different width in same machine on certain scopes.The surface of PVC ceiling panel can be treated by printing or hot stamping.

Plastic extrusion machine for PVC ceiling panel is used to manufacture PVC ceiling panel, PVC wall panel with width normally from 200mm to 600mm with different section shape and height.The popular surface treating are hot stamping,printing or lamination.

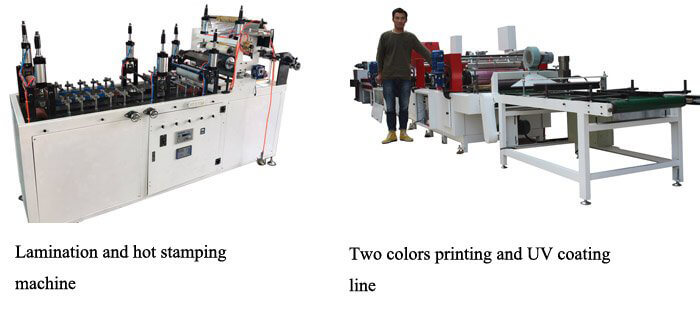

Surface treating ways of PVC ceiling panel:

1.Two colors printing

2.Hot stamping (or called trasfer printing)

3.Lamination

Advantage of Eans plastic extruder machine for PVC ceiling panel:

1.Best brands,ABB inverter,Schneider eletric,RKC temperature contoller etc

2.We supply whole production line with turnkey solutions.

3.High capacity,800 to 1200 square meter in 55/110 extruder

Parameter of plastic extrusion machine for PVC ceiling panel:

| Model | SJSZ48/113 | SZSZ55/110 | SZSZ65/132 |

| Applicable width | 150 to 200mm | 250-300mm | 400-600mm |

| Extruder | SJSZ48/113 | SJSZ55/110 | SJSZ65/132 |

| Capacity(kg/24hours) | 2200 | 3000-3500 | 4000-5000 |

| >800m2/24hours | >1200m2/24hours | >1600m2/24hours |

Machine list:

| 1 | 300/600 PVC mixer | Output:800-1000kg/h |

| 2 | Two colors printing machine line | Speed: 0-30m/min |

| 3 | Crusher | Motor power:22kw |

| 4 | SMF500 PVC pulverizer | Output: 200kg/h |

Eans machinery supply PVC ceiling panel machine line.Such as whole PVC ceiling panel production line,raw material,formula,technical service and best after-sale service.

Our factory is located in Wuxi city which is closed to Shanghai city.It takes 30 minutes from Shanghai to Wuxi city by fast train.And it spends 2 hour from Guangzhou to our city by plane.

Welcome to visit our factory!