EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

Eans Machinery offer China best Top Quality WPC Fluted Wall Panel Making Manufacturing Process Machine, WPC profile making machine

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Eletric: |

|

Temperature controller: |

|

Steel: |

|

Speed: |

|

Screw and barrel: |

|

Guarantee time: |

|

Votage: |

|

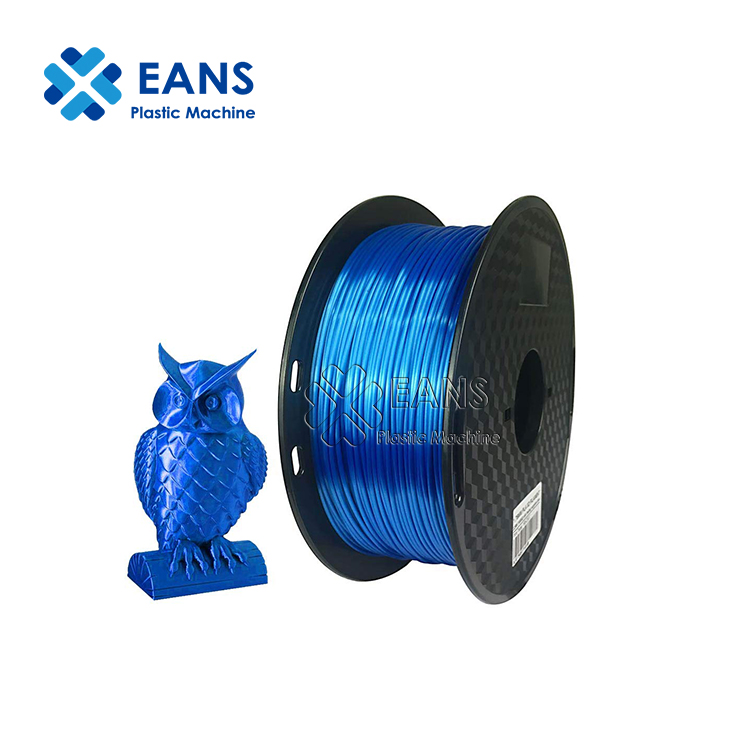

The filament extruder is suitable for normal temperature materials such as ABS/PLA/HIPS/PETG/NYLON/PC, and also suitable for high-temperature materials such as PEEK/PEI/carbon fiber.

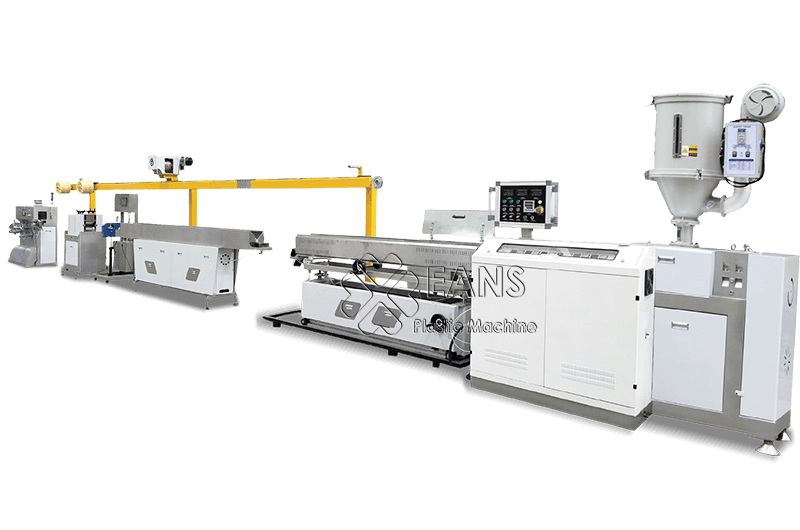

The filament production line consists of a high precision extruder, high-quality alloy steel mold, constant temperature water tank, servo tractor, automatic storage line rack, and automatic winding device. This series of production lines all adopt PID closed-loop control and PLC control program, which is convenient and quick to operate.

Features:

1 Big capacity compared with other suppliers who use the same model.

2 Lowest tolerance: +/- 0.03 mm. even +/- 0.02 mm.

3 Both 1.75 and 3.00mm filament diameter

4 It can process multi-materials like PLA ABS PET PA HIPS.

5 Easy operation: SIEMENS PLC full-auto controlling system

6 Stable quality, we have not received any passive talks from our customers

7 Oversea service, installation, staff training, and technical support.

Main Equipment of the ABS/PLA Filament Extruder:

No. | Item | Qty |

1 | Hopper Dryer | 1 Set |

2 | SJ45/28Single Screw Plastic Extruder | 1 Set |

3 | Die | 2 Sets |

4 | Cooling water bath with Calibration | 2 Sets |

5 | Laser Gauge | 1 Set |

6 | Haul-off machine | 1 set |

7 | Horizontal storage rack | 1 set |

8 | Double station winder | 1 set |

Finished 3D Filament

FAQ:

We will arrange our engineer to the customer factory for installation and teach local workers to operation and maintenance. We also can send the experienced master to work at the customer's factory for three months or more according to requirements.