EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

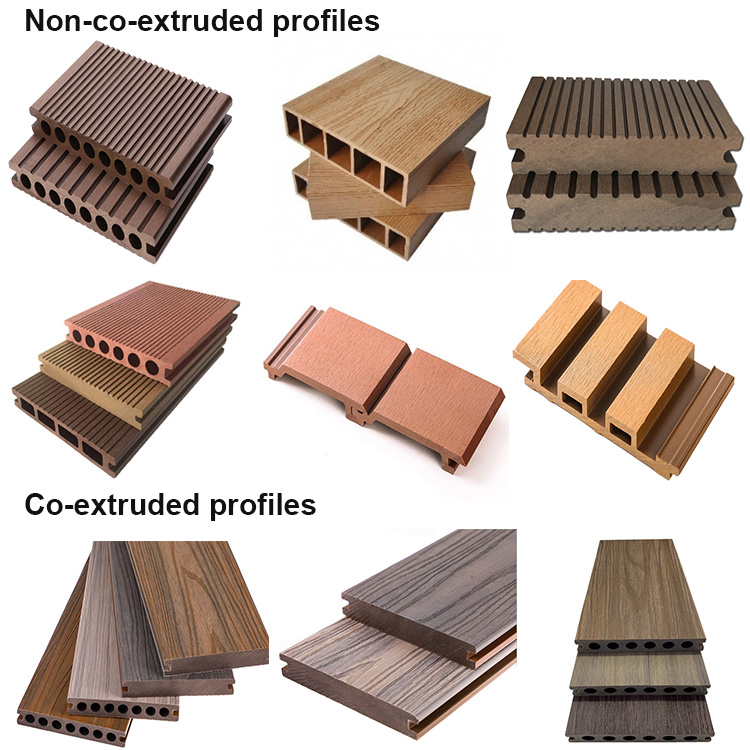

Eans Machinery offer outdoor waterproof interlocking PP PE WPC wood plastic composites fence decking flooring board sheet tiles extrusion production machine line

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Eletric: |

|

Temperature controller: |

|

Steel: |

|

Speed: |

|

Screw and barrel: |

|

Guarantee time: |

|

Votage: |

|

2. Changing the moulds to produce many kinds of different PVC profiles.

3. Auxiliary machine: Mixing unit, crusher, pulverizer, laminating machine ....

Parameters:

| Model | SJ 51 | SJ 65 | SJ 80 | SJ 92 |

| Diameter of screw | 51/105 | 65/132 | 80/156 | 92/188 |

| Speed ( KG /H) | 120 | 260 | 400 | 800 |

| Weight ( KG ) | 3200 | 4000 | 5000 | 7000 |

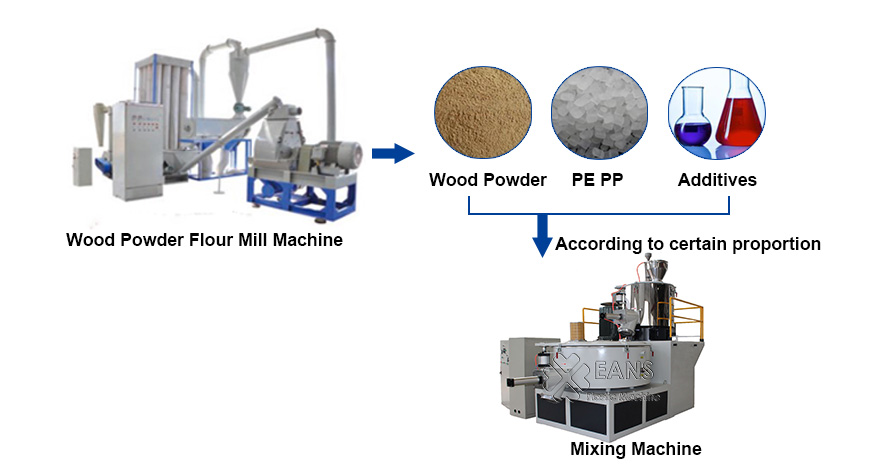

Flow Chart of PE PP Wood Plastic Composite Profile Production Line

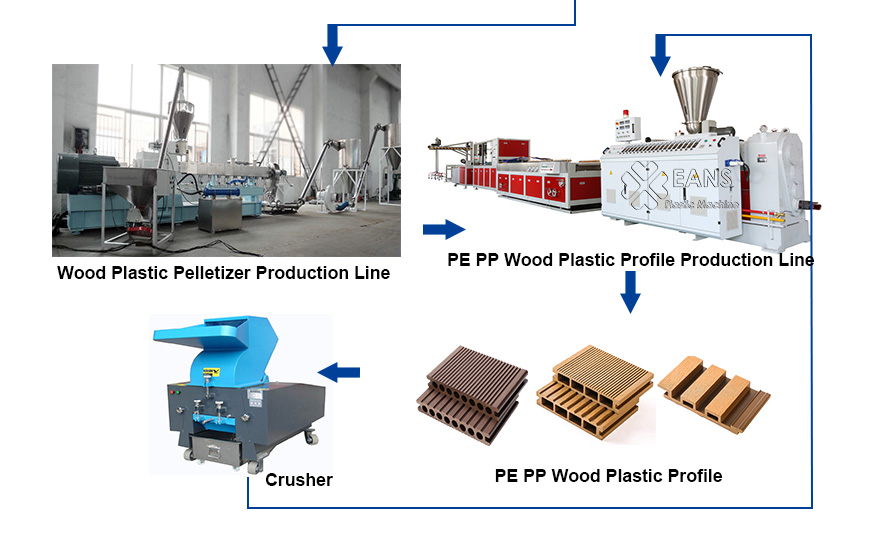

Samples Display

The wood-plastic composite material contains plastic, so it has a good elastic modulus. In addition, because it contains fiber and is fully mixed with plastic, it has physical and mechanical properties such as compression resistance and bending resistance equivalent to hardwood, and its durability is significantly better than ordinary wood materials. The surface hardness is high, generally 2--5 times that of wood.

FAQ:

We will arrange our engineer to customer factory for installation and teach local workers to operation and maintenance. We also can send experienced master to work at customer's factory three month or more according to requirements.