EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

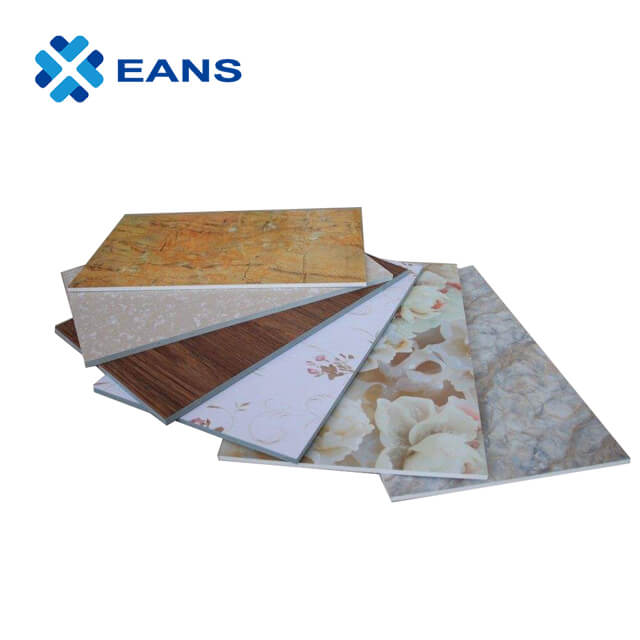

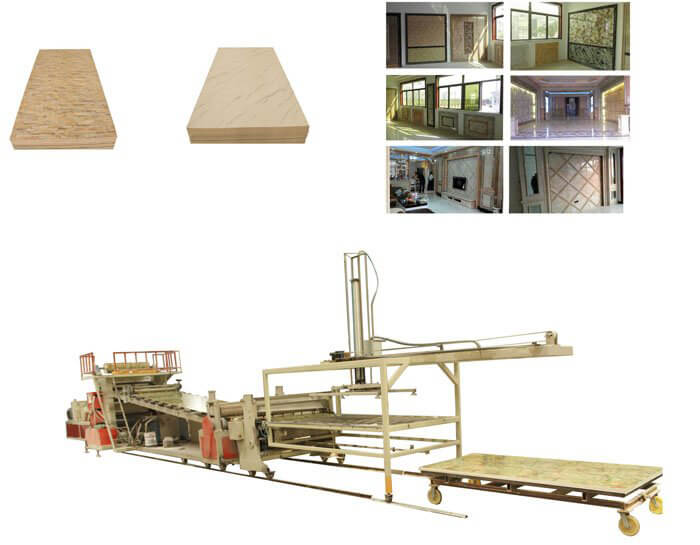

PVC marble sheet production line is utilized to produce PVC imitation marble sheet.The final size of PVC marble sheet is 1220*2440*3.5mm(W*L*T).The surface of PVC marble sheet need UV coating.After UV coating,the surface of PVC marble sheet is high glossy and anti-scratch.

PVC imitation marble sheet production line is used to produce PVC marble sheet with width of sheet 1220mmm and length of sheet 2440mm length, thickness mostly 2.8 to 3.5mm.The surface of PVC marble sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color, It can produce PVC marble sheet with different color. After coating UV glossy varnish, the surface of PVC marble sheet is high glossy and anti-scratch.

PVC marble sheet is widely used for hotel, office building, super market, KTV, massage club and other public area

Features of PVC marble sheet production line:

*high output---One production line can produce 500 pieces per day at least.

*speed controlled by inverter, saving power and easy to adjust speed

*extruder temperature controlled by RKC intelligent controller, temperature fluctuation self adjusting. PLC touch screen can also be equipped according to customer’s favorite.

Main parameter of PVC marble sheet production line:

| No | Item | Parameter |

| 1 | Extruder | 80/156 |

| 2 | Thickness of sheet | 2.8-3.5mm |

| 3 | Size of sheet | 1220*2440mm |

| 4 | Weight of sheet | 17-25kg/piece |

| 5 | Output | 530sheets/day;About 10Tons/24h |

| 6 | Size of machine | 25x2.5x3m |

| 7 | Suggested workshop size | 60x24x6m |

Welcome to send inquiry to get more details!