EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

PVC corner profile making machine is used to manufacture PVC corner profile, PVC profile, etc.

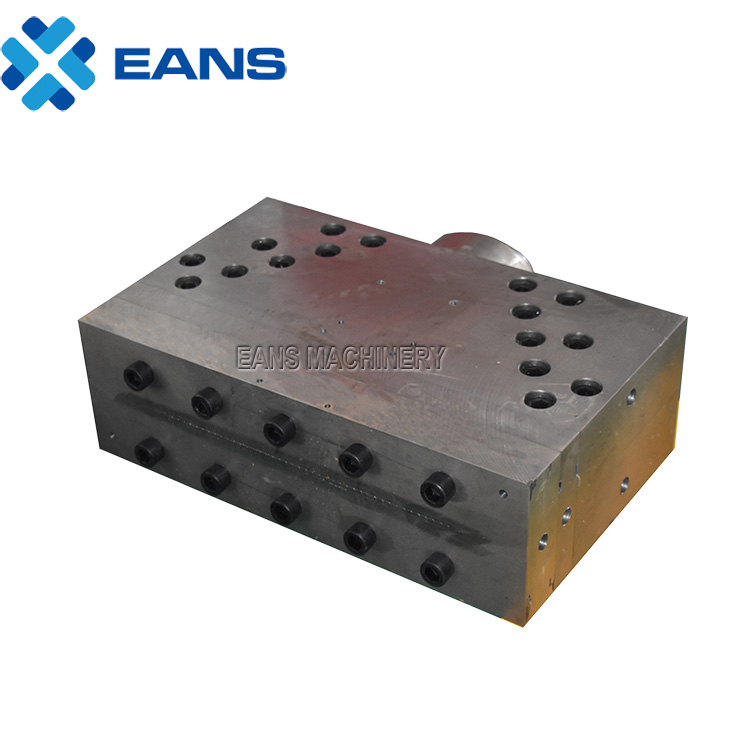

PVC profile production line is widely used in the production of window and door profiles, panel, foam profiles and decorative profiles, etc. This unit is composed of accurate extruder, die(mold),vacuum calibration water cooling bath, haul off, cutter, etc. Main machine and haul off unit adopt imported frequency converter of speed control, and this line is matched with stainless steel calibration bath(calibrating die).The hauling speed is steady, the measure is precise. Cutter uses PLC to control and the cutting length can be set arbitrarily. The whole line has the advantages of high automation, stable performance, large output and high efficiency, etc.

Advantage of PVC corner profile production line:

1.Best brands,ABB inverter,Schneider eletric,RKC temperature controller,Siemens motor

2.We supply whole production line with turnkey solotions.

3.High capacity(2000 square meter in 24 hours with 55/110 extruder).

4.Best after-sale service.

5.One-stop service.

Parameter of PVC corner profile extrusion machine:

| Model | SZSZ55/110 |

| Applicable width | 250-300mm |

| Extruder | SJSZ55/110 |

| Capacity | 150-180kg/h |

For more details,please send inquiry to us!

Eans machinery supply complete PVC corner profile production line with trunkey solutions!