EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

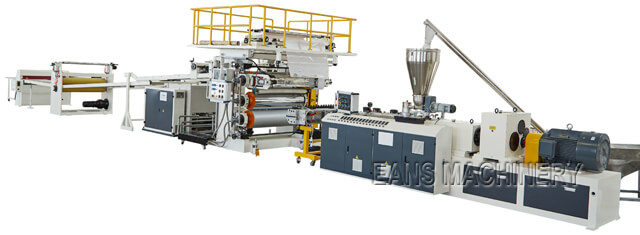

PVC lamination marble sheet production line from Eans Machinery is advanced in skill and high automation.The based material extrusion,wood grain embossing,color film,and top surface UV coating with high glossy.

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Automatic PVC marble sheet production line with PLC control:

PVC lamination marble sheet making machine from Eans Machinery is advanced in skill and high automation.The based material extrusion,wood grain embossing,color film,and top surface UV coating with high glossy.

Machine details of PVC marble sheet extruder machine with PLC control :

| No | Machine name | Quantity |

| 1 | SJSZ80/156 conical twin screw extruder | 1set |

| 2 | Hanger plate mold | 1set |

| 3 | Three roller calendaring machine | 1set |

| 4 | Cooling bracket and trimming device | 1set |

| 5 | Traction machine | 1set |

| 6 | Feeding device | 1set |

Main advantage of Eans PVC marble sheet production line with PLC control:

1.The screw adopt the design of special mixing material function and high plasticization capacity.This guarantee the uniformity of plastic mleting,coloring and high output.

2.Clothes rack type mold die adopt double throtting design,which can make more precision of adjusting of flooring thickness.

3.The ±1℃ precision degree of temperature control can control the plasticization process,thickness and surface smooth of sheet accurately.

4.The roller position can be put by vertical or horizontal,which can give more selection basing on the different thickness of sheet

5.The screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

Rigid core flooring is extruded by extruder and T-die extrusion PVC substrate,with three roller calendar,PVC color film layer and high glossy UV varnish coating.

Machine running video of PVC marble sheet production line with PLC control: