EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

What is PVC edge banding?

PVC edge banding is a material for protecting, decorating and beautifying the section of the furniture board. It can make a piece of furniture show the overall effect of clear wood grain and colorful colors.

The PVC edge banding is made by PVC resin, calcium carbonated and other plastic processing aids. Thickness from 0.3 mm to 3 mm, width from 12 mm to 80 mm.

The features of PVC edge banding:

PVC edge banding is made of polyvinyl chloride as the main raw material, adding plasticizers, stabilizers, lubricants, dyes and other auxiliaries, and mixing and pressing together thermoplastic coils. Its surface has wood grain, marble, cloth grain and other patterns and patterns, and the surface gloss is soft, with the realism and three-dimensional sense of wood; it has a certain degree of finish and decoration, and has certain heat resistance, chemical resistance, corrosion resistance, The surface has a certain hardness. The main function of the edge banding is to seal the section of the board, so as to avoid the damage to the board by the environment and adverse factors (mainly moisture) in the process of use, and prevent the formaldehyde inside the board from volatilizing, and at the same time achieve the effect of decoration.

PVC edge banding production process:

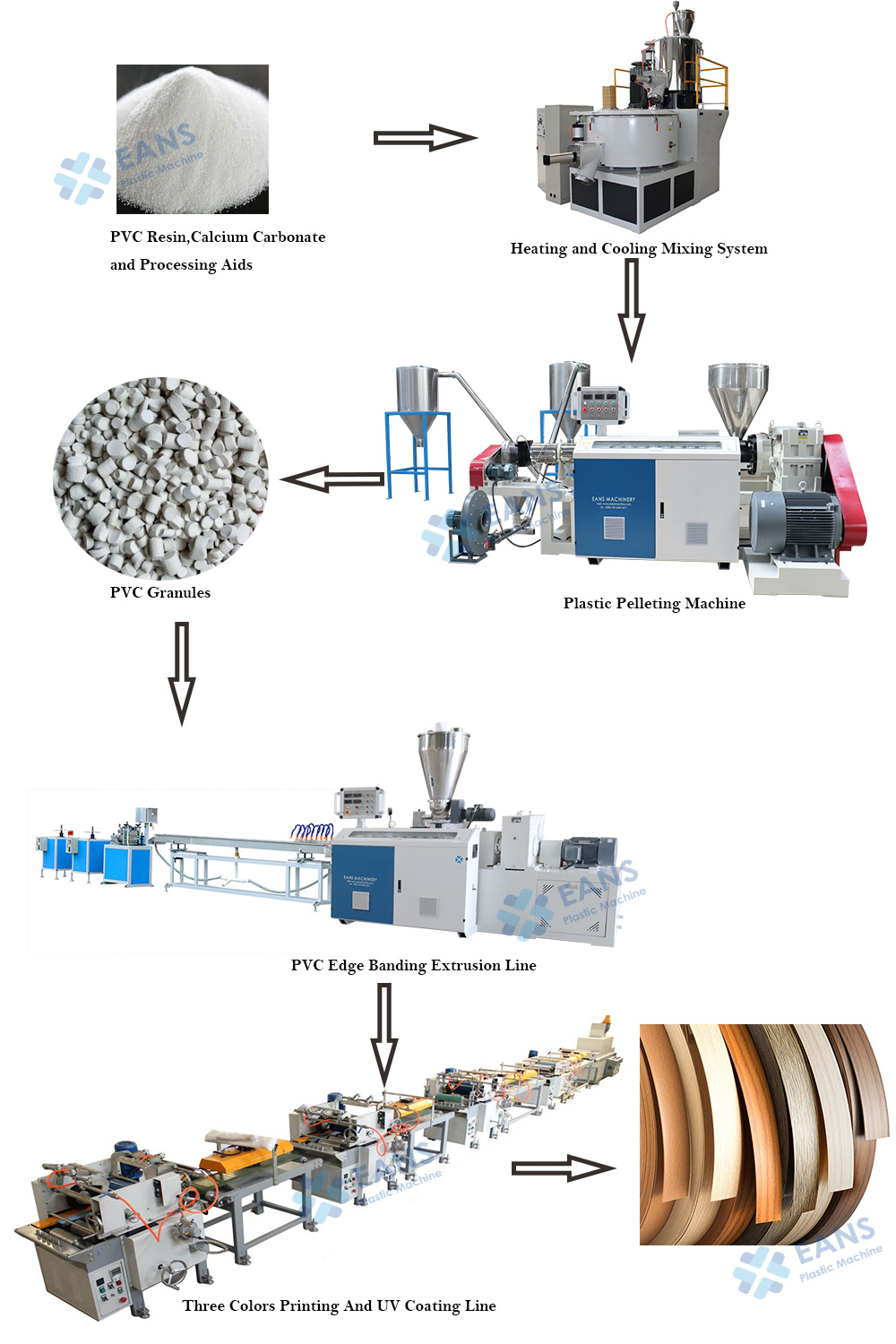

PVC edge banding production line consists of raw materails mixing system, PVC edge banding extrusion line, three colors printing and UV coating machine and so on.

Please check the flow chart of PVC edge banding production line:

Welcome your inquiry for PVC edge banding making machine!

Tel: +86 181 3613 9980 Email: sales@eansmachine.com