EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

Last month, PVC wall panel production line be tested at Eans' workshop , This extruder adopts a vertical type gearbox, it is better for plasticizing. Our extruder is fast to heat up, so only needs few time to test until it is successful.

PVC Wall Panel Production Line Machine List

1. Automatic raw materials feeder - 1 set

2. Double screw extruder - 1 set

3. Die and calibration mould - 1 set

4. Vacuum cooling table - 1 set

5. Hauling off - 1 set

6. Auto cutting machine - 1 set

7. Finished PVC wall panel stacker - 1 set

Features of PVC Ceiling Wall Panel Extrusion Line:

- Fetching in Europe and America advanced technology and uniting with domestic condition, our company develop this production line.

- Easy and convenient for operation and maintain

- Economical price, suitable for large scale investment.

- This production line is used to manufacture PVC wall panel with width normally from 250mm to 300mm with different section shape and height.

- The surface of PVC ceiling / wall panel can be treated by hot stamping printing or lamination machine, which can make marble, wooden design on surface of PVC ceiling or PVC wall panel.

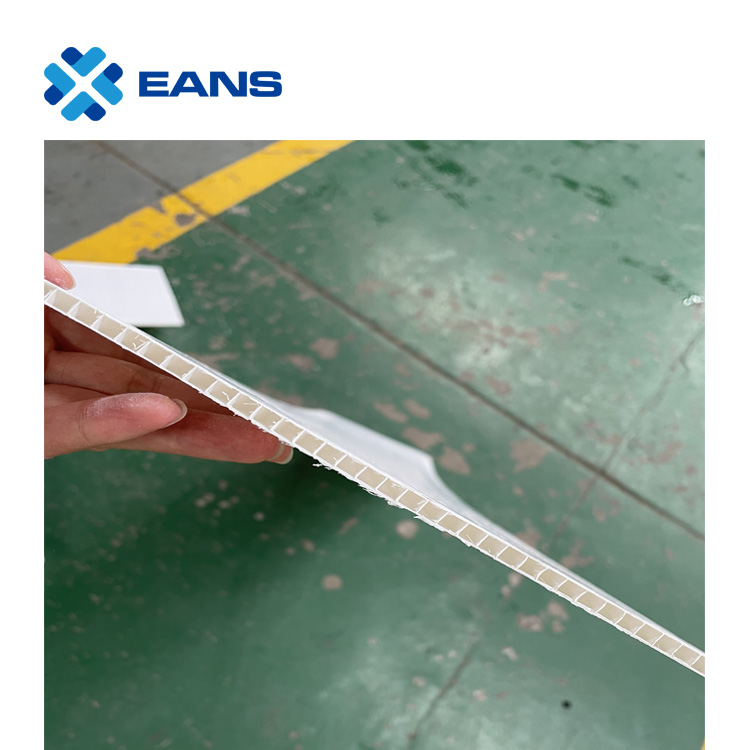

The customers visited the on-site test machine process through video. Attached is the hollow PVC wall panel with vertical design, the section drawing is beautiful, customer is satisfied with this PVC wall panel.

The following is the working video of PVC wall panel production line: