EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

Contact Person: Alice Shi WhatsAPP/WeChat: +86 180 0156 9980 Email: sales1@eansmachine.com

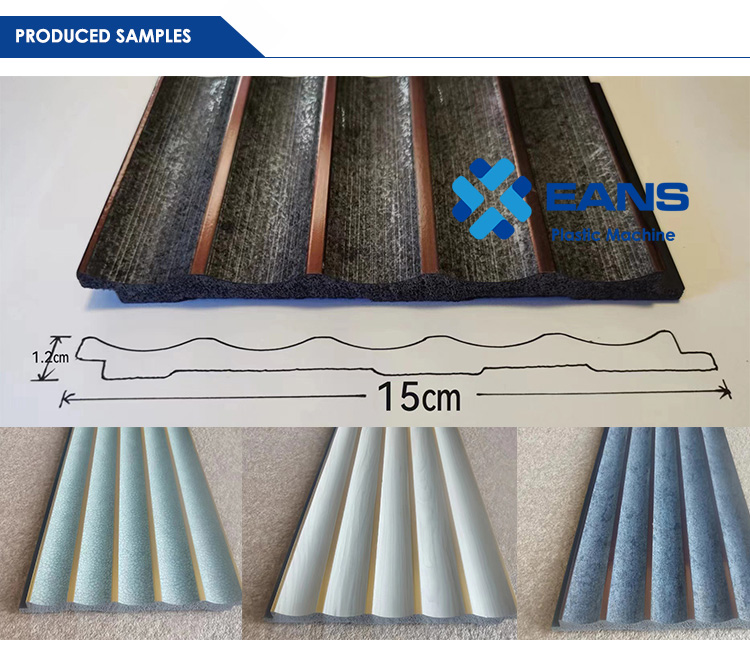

The PS wall panel production line is mainly used to produce PS wall panels and PS louver panels. PS wall panel production line is also widely used to make photo frames, skirting boards and so on. The production line has the advantages of easy foaming, high efficiency and low production cost. This production line has the advantages of high degree of automation, simple operation, stable and reliable continuous production and so on.

Model | SJ 75 | SJ 90 | SJ 120 | SJ 150 |

| Diameter of screw | 75 mm | 90 mm | 120 mm | 150 mm |

| Co-extruder | SJ 35 | SJ 45 | SJ 45 | SJ 65 |

| Capacity | 45-50 KG/H | 60-70 KG/H | 90-100 KG/H | 100-120 KG |

Single Screw Extruder

Water Cooling Tank

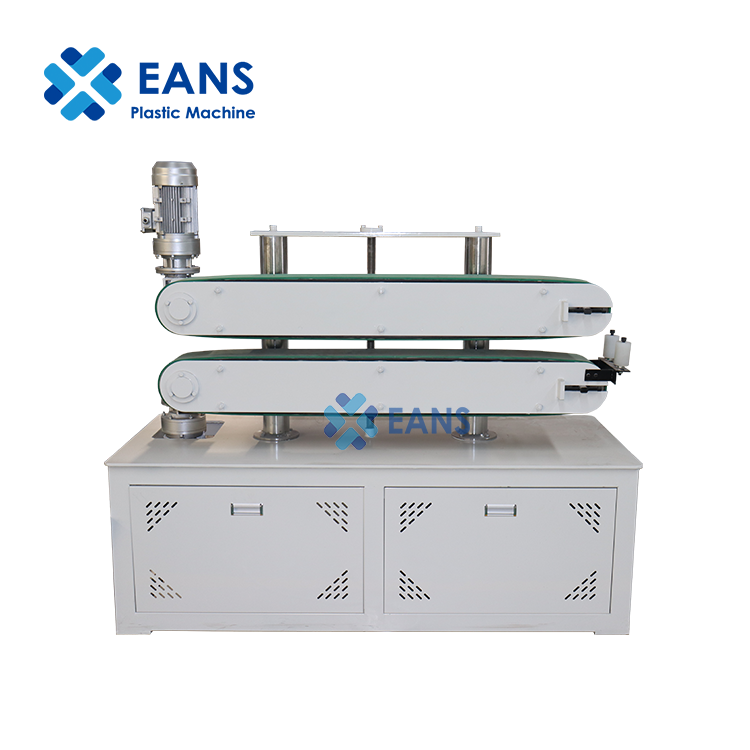

Belt Haul off Machine

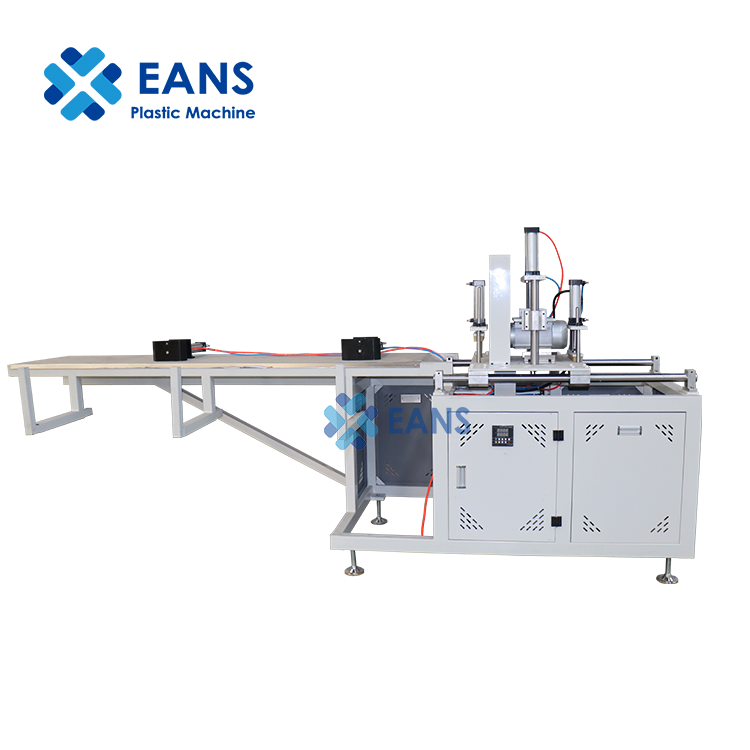

Cutter and Stacker

Hot Stamping Machine

1. This machine is special designed for transfer the designs from foil on the PS louver panel, PS wall panel, PS photo frame and other PS products.

2. It adopts pneumatic to control the rollers and the hot stamping angle is adjustable.

3. Automatic and synchronous winding of hot stamping foil.

Application:

The PS wall panel production line is mainly used to produce PS wall panels and PS louver Panels. PS wall panel production line is also widely used to make photo frames, skirting boards and so on.

PS Wall Panel are new popular decorative panels. In interior decoration, PS wall panels are used to cover an existing wall to add visual appeal or disguise imperfections. PS Wall Panels are avaliable in a variety of finishes and textures.

It provides you with a lightweight panel that doesn't compromise durability. They feature easy installation to studs, ceiling joists, furring strips or solid surfaces. They can also be used as drop in ceiling tiles. The panels can be easily cut with standard hand and power saws.

The new Eco-friendly materials bring the healthy environment, no voc, no formaldenhyde and no any metal heavy products.